Ein freudiger Blog-Post

… about the tough repair of a burnt-out Zing 24 laser cutting system from Epilog.

Hello dear readers and welcome to the freshly baked year 45^2. It starts with good news: Our Peppel machine has seen the laser light of day and has learned to walk again - and most recently in the middle of the rest of the Stadtwirtschaft chaos. I'll write a little summary about the project and say thank you to all the contributors and co-thinkers.

Background

Sometime in late spring 2024, our founding member Maik asked in the FabLab chat group whether we could imagine reviving a broken laser cutter. He could get two machines from machine's hell that had been killed by misuse. They were very badly damaged and no longer economically repairable in terms of warranty and resale, but “two make one” as the saying goes and with a little love and know-how, it might be possible to fix it.

As we haven't had a laser in the club for a long time, but always wanted a decent one that was suitable for the workshop, we didn't say no to the Epilogs, as we had already had good experiences with the Zing devices in previous years (VOW Wanderlaser, Saskia's laser and Mario's experiences). So Maik brought us two well-fried tin boxes - a Zing 16 and a Zing 24 - with coked-up electrics, a dirty interior and lots of funny surprises by car to Chemnitz. That sealed the deal and the challenge was accepted!

What have we done?

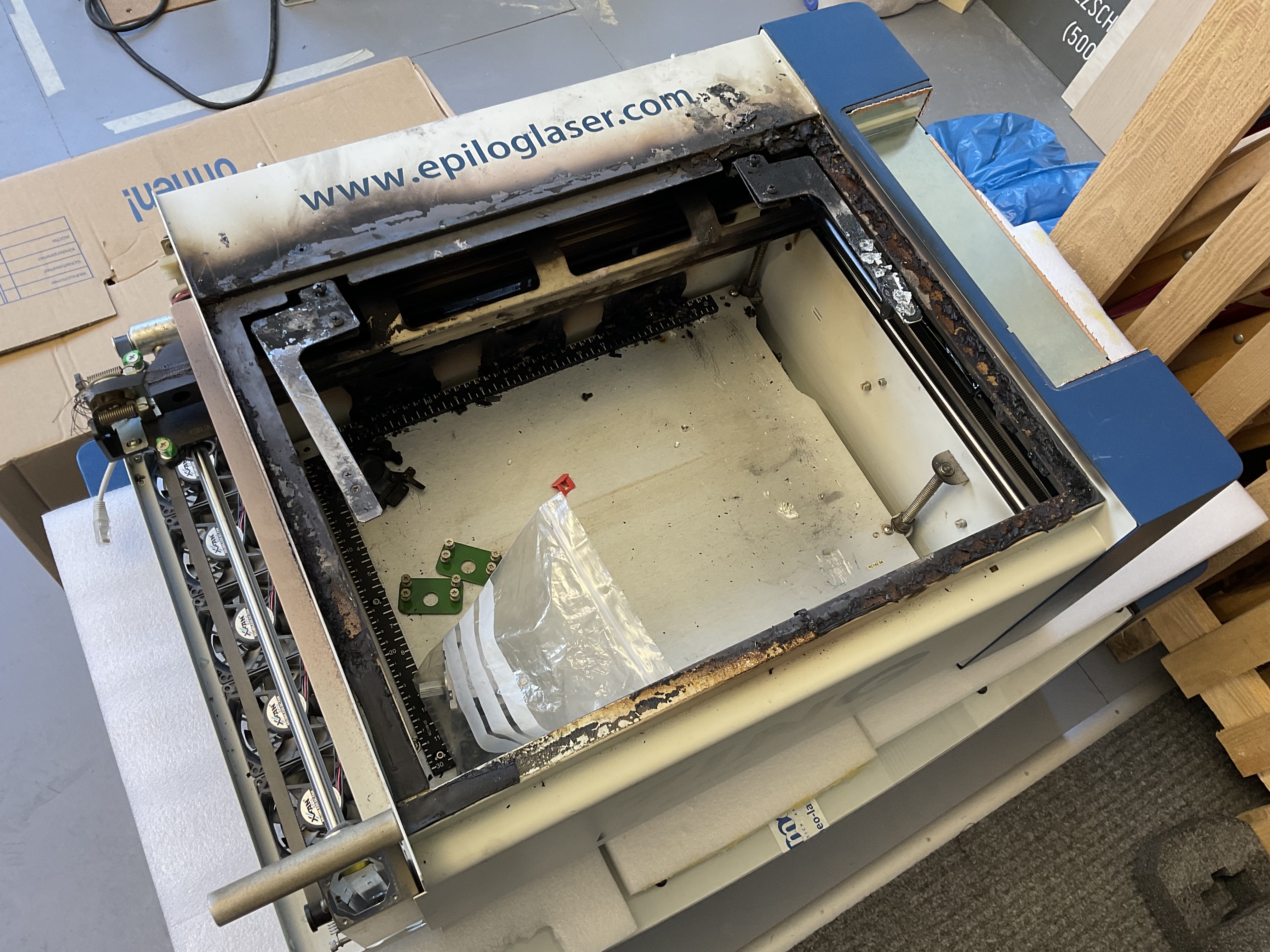

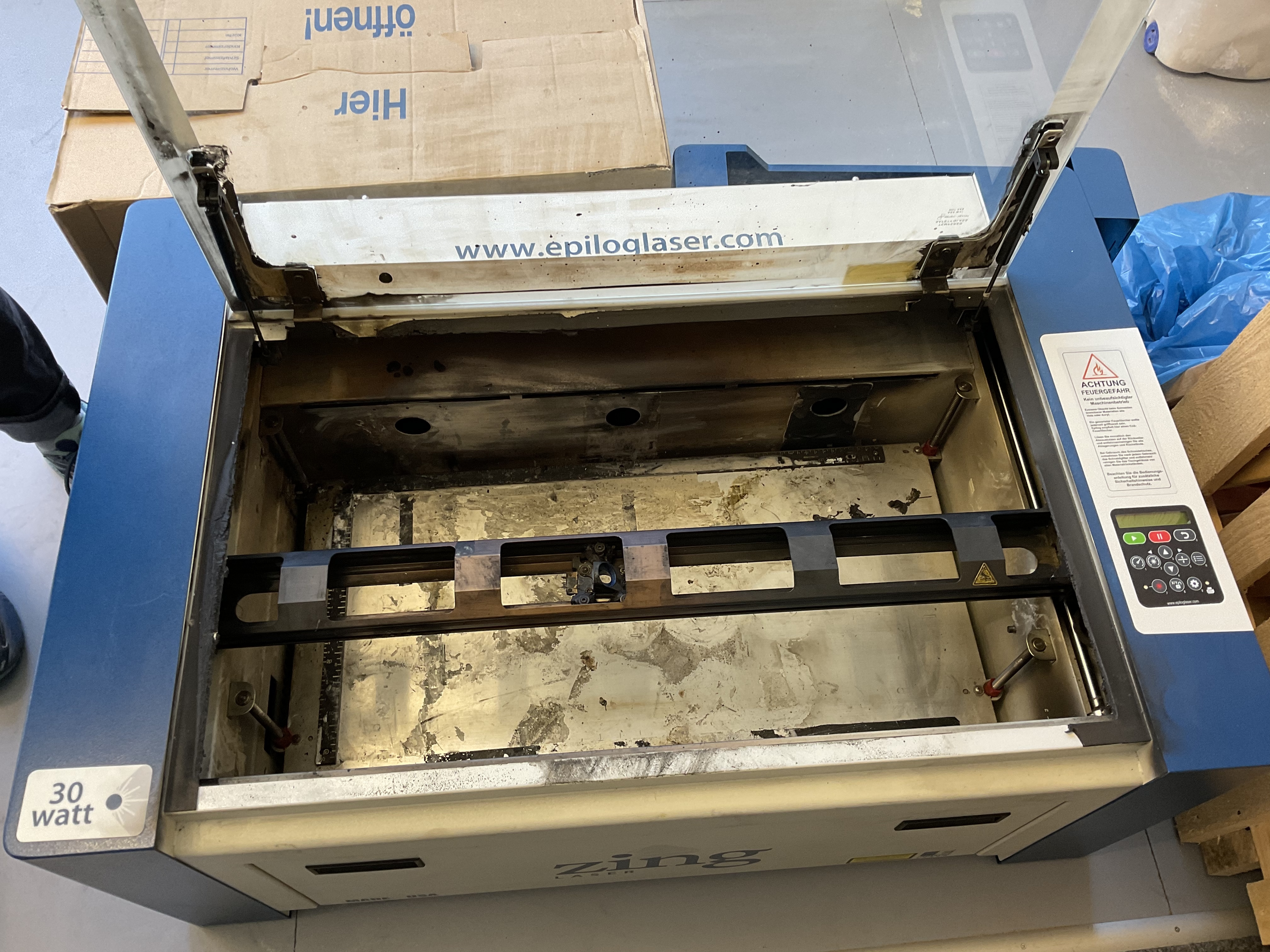

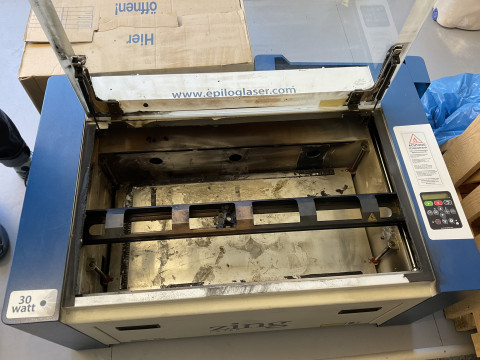

Everything at once! After an on-site inspection, the two lasers were in a catastrophic state. In addition, we were unable to work on the premises of the Stadtwirtschaft (without an existing workshop, repairs are extremely difficult) and therefore had to store the devices temporarily at Markusstr. 21, where we were also able to start the inspection and repair after we had gathered everything we needed and moved the two heavy devices several times.

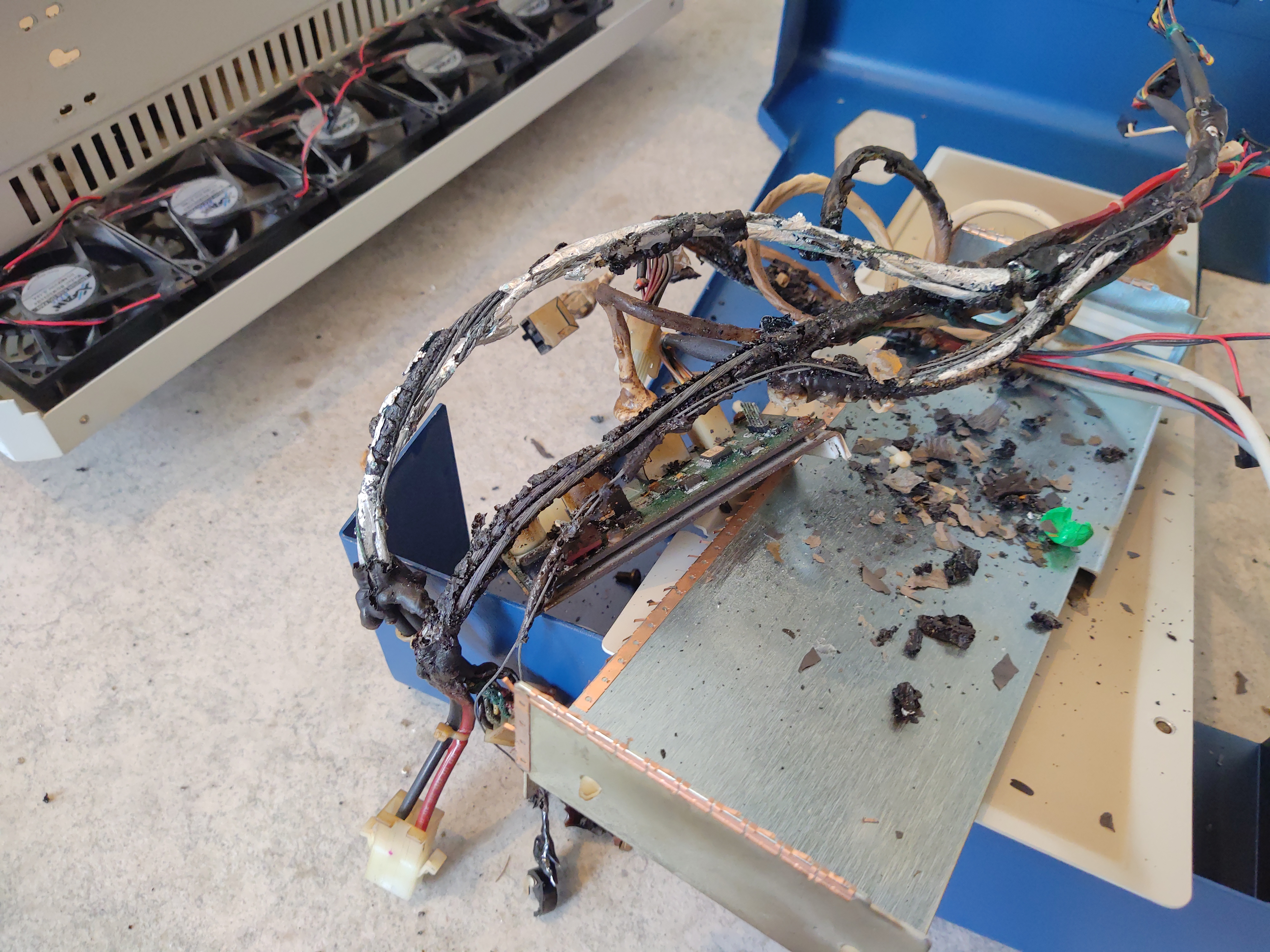

Initially, we decided to use the smaller Zing 16 as a spare parts donor because it was ultimately really beyond repair. However, in addition to dust and dirt, it donated some important cable harnesses, screws and a still usable CO² laser source for the Zing 24. The latter consumed vast amounts of water and cleaning agents to remove all the contaminants from regular laser use and the fire and to get to the basic substance. The cleaning alone took more than half a week of a full day shift.

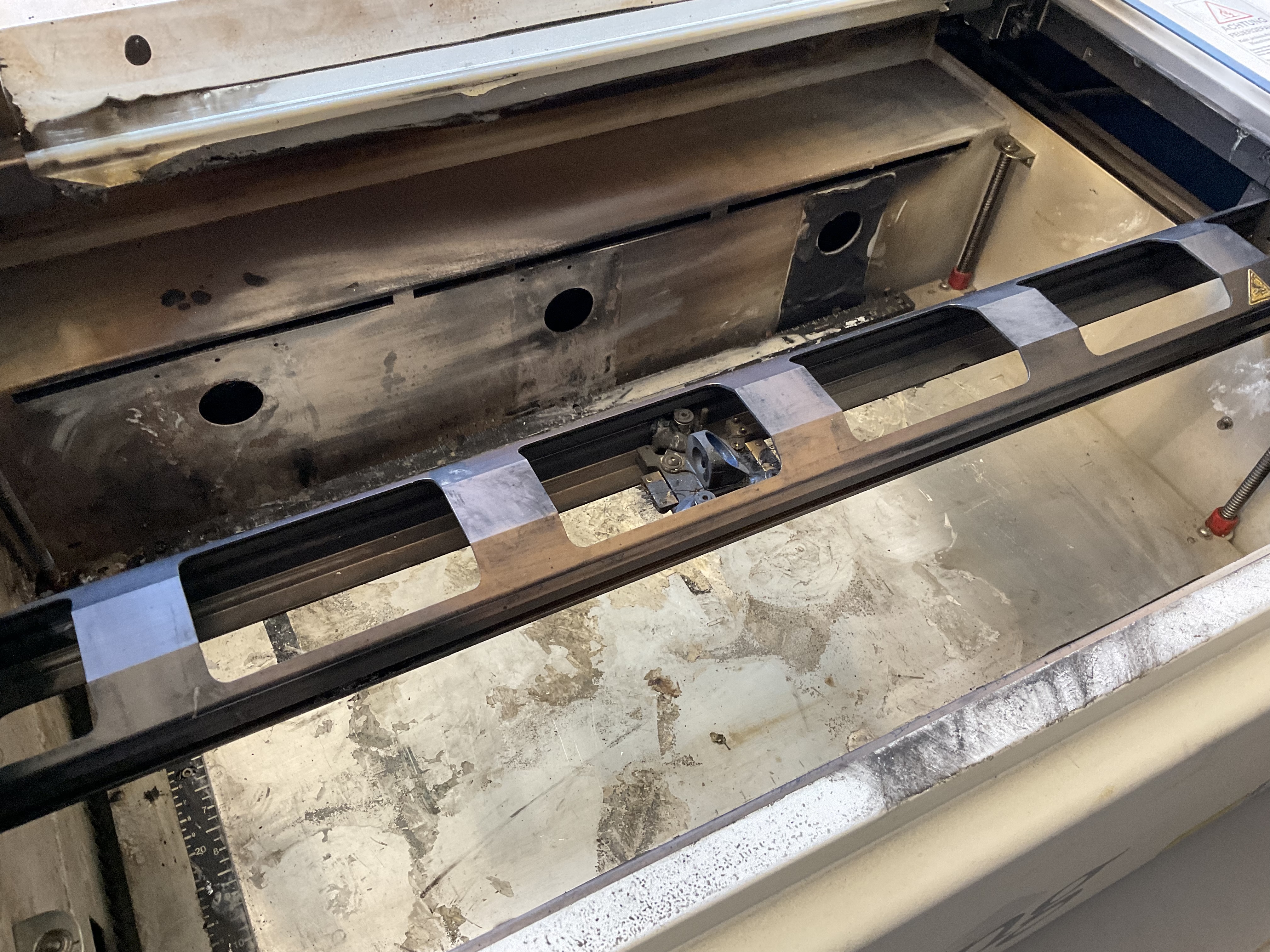

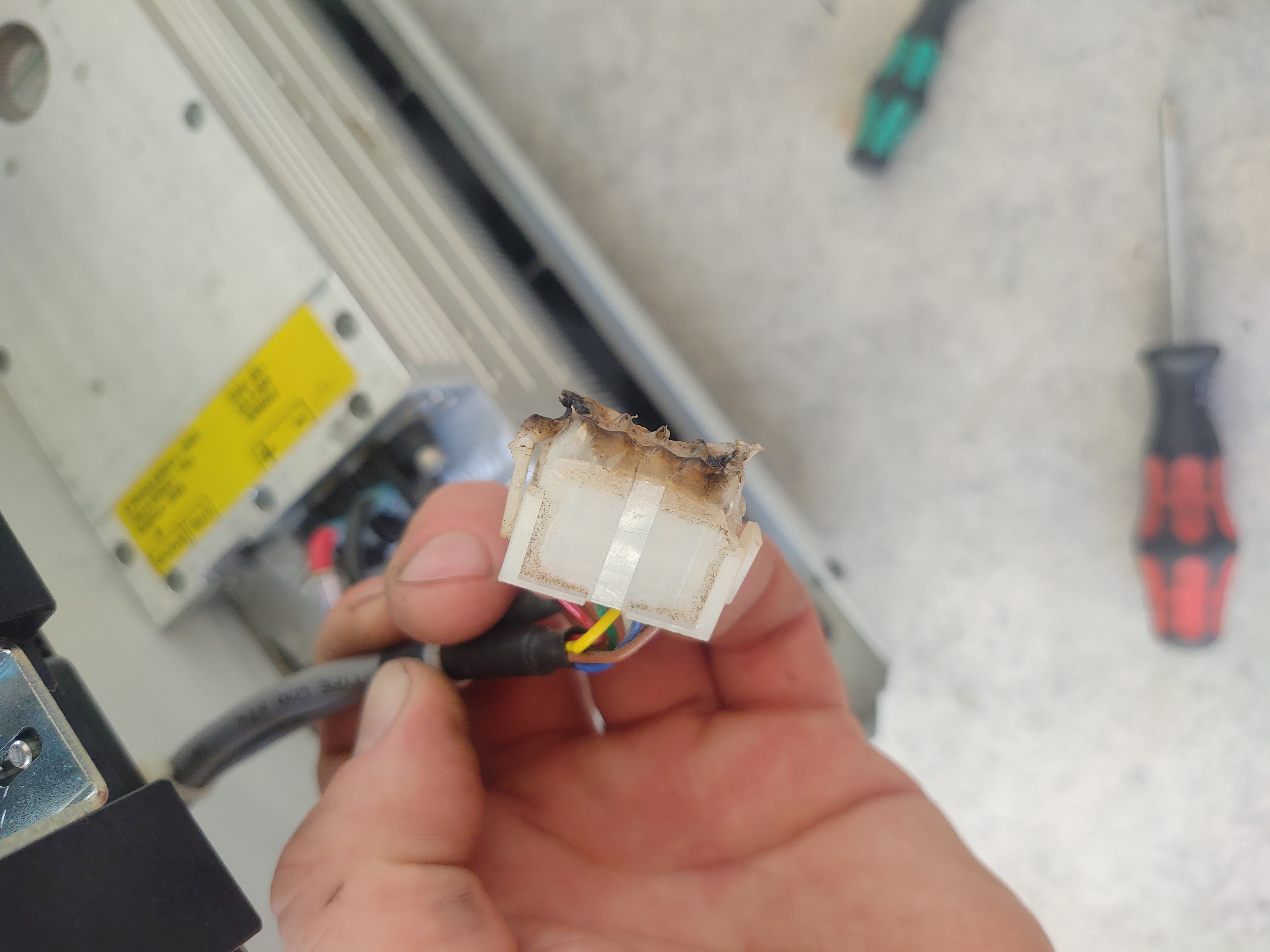

The cause of the fire was probably a plastic part that burst into flames. This is because thermoplastic residue was everywhere in the interior and had crept into various cracks and components. Cleaning with a hot air dryer, spatula, sandpaper etc. was correspondingly time-consuming - it also melted several electronic cables and plugs, caused the optical lenses to crack, put a stepper out of action, spread smoke on the circuit boards and caused all the seals to stick together. Important mechanical components such as toothed belts and gas pressure springs also melted or burst. During cleaning, we also found countless laser parts that had slipped into the interior. These were the first indications that no professionals were at work here and that this machine had been driven to wear and tear.

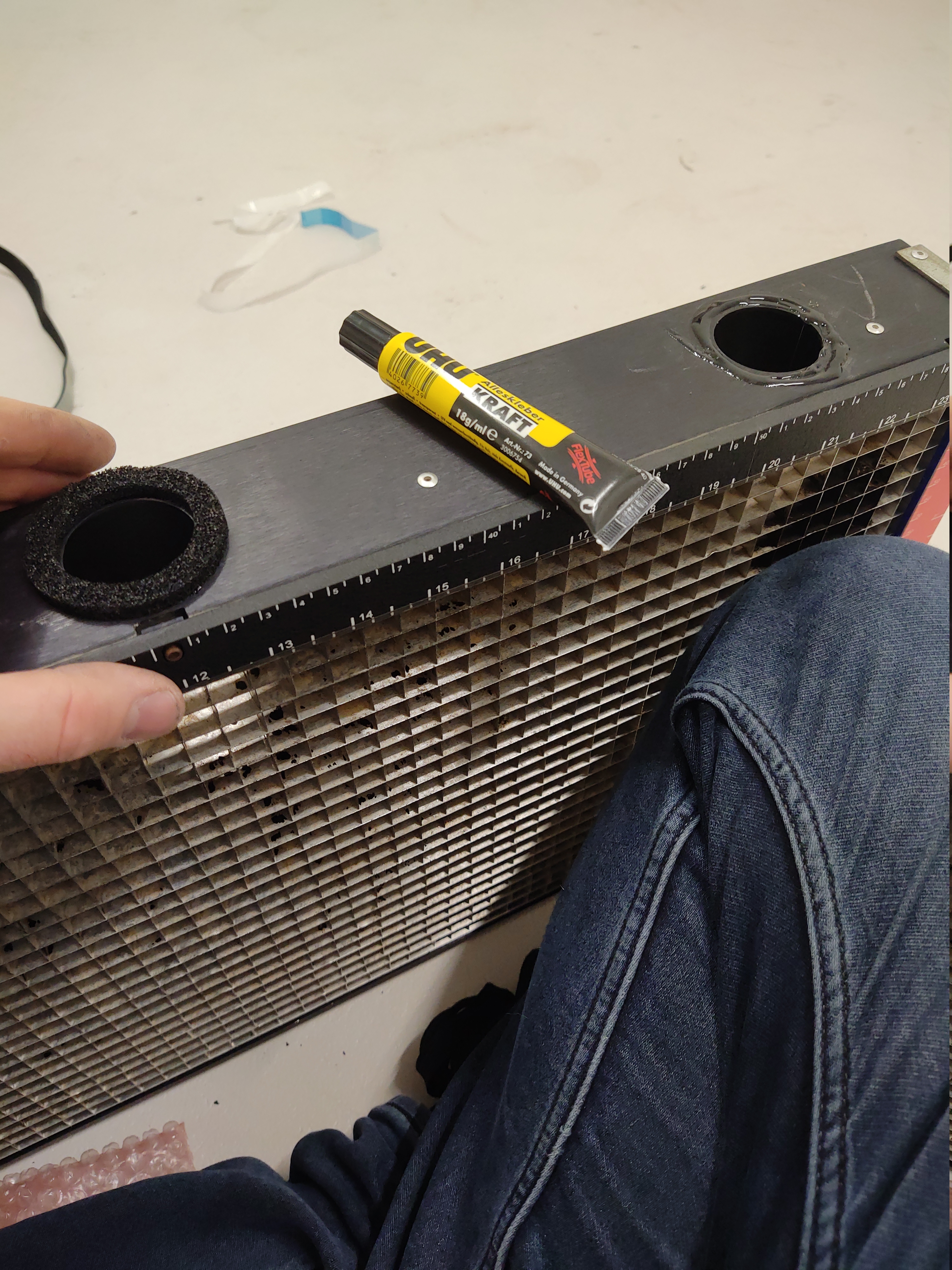

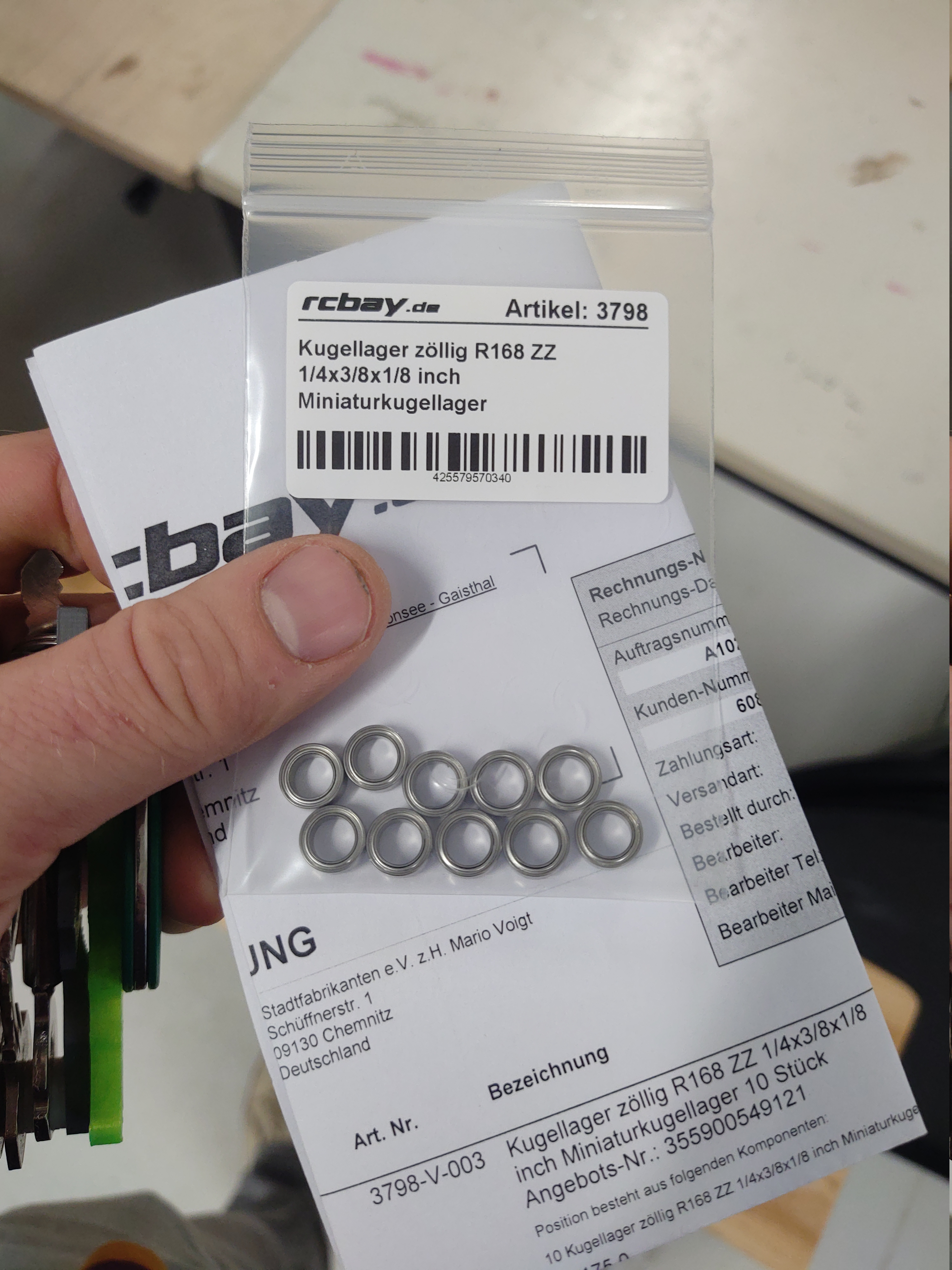

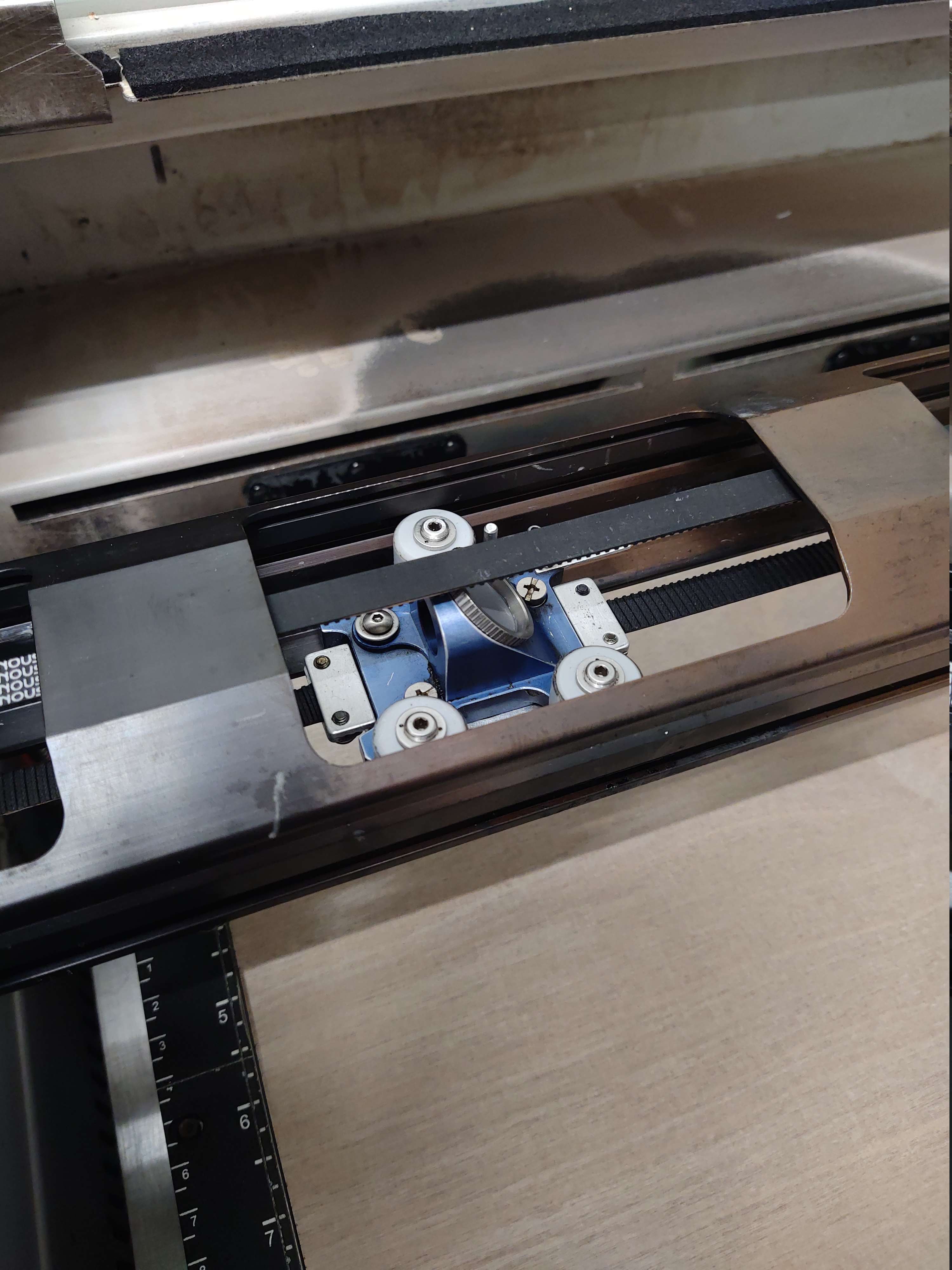

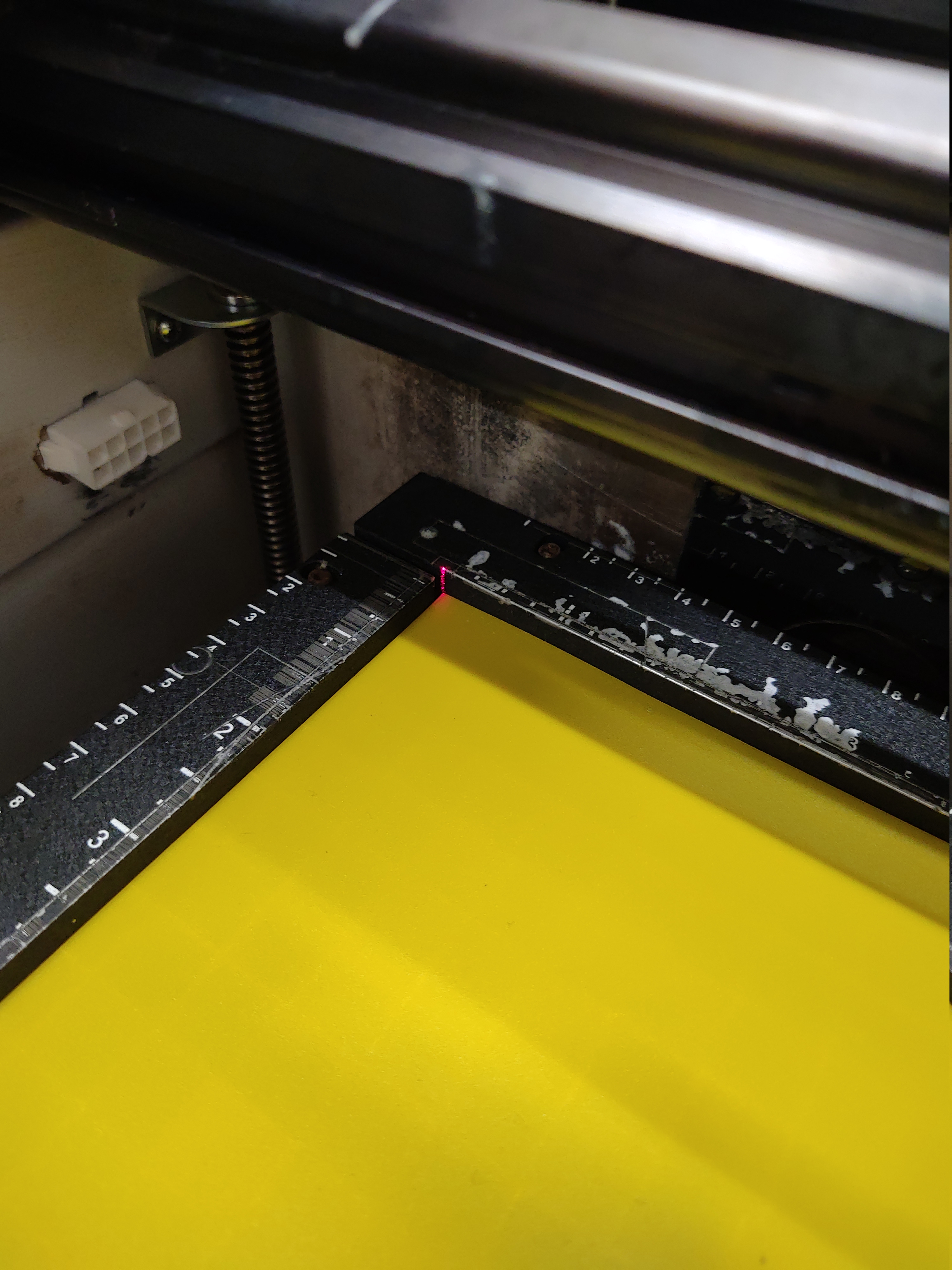

After or during cleaning, we were able to create a parts list and a to-do list at the same time, detailing everything that would probably be needed to repair the appliance. A wide range of tools, spare parts and documentation steps quickly emerged. Our replacement list ultimately included items such as new reed contacts, a toothed belt for the X-axis, new foam parts for the glass cover, a new focus lens and a new mirror for the carriage, gas springs, plastic rivets, miniature ball bearings for the carriage and so on.

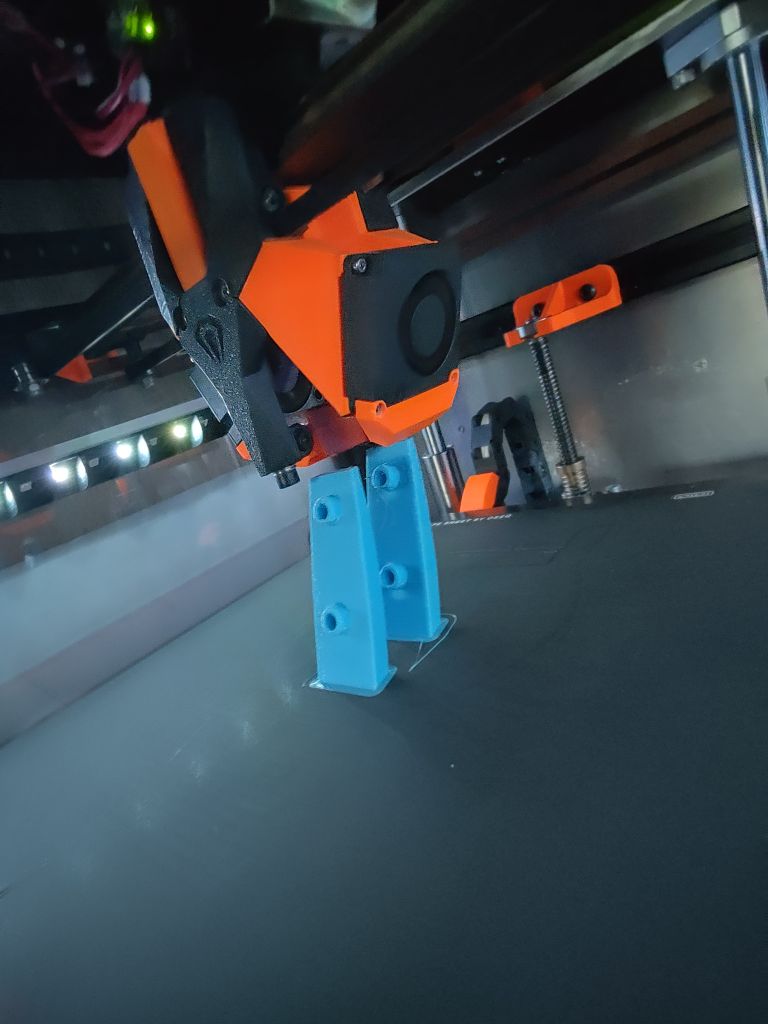

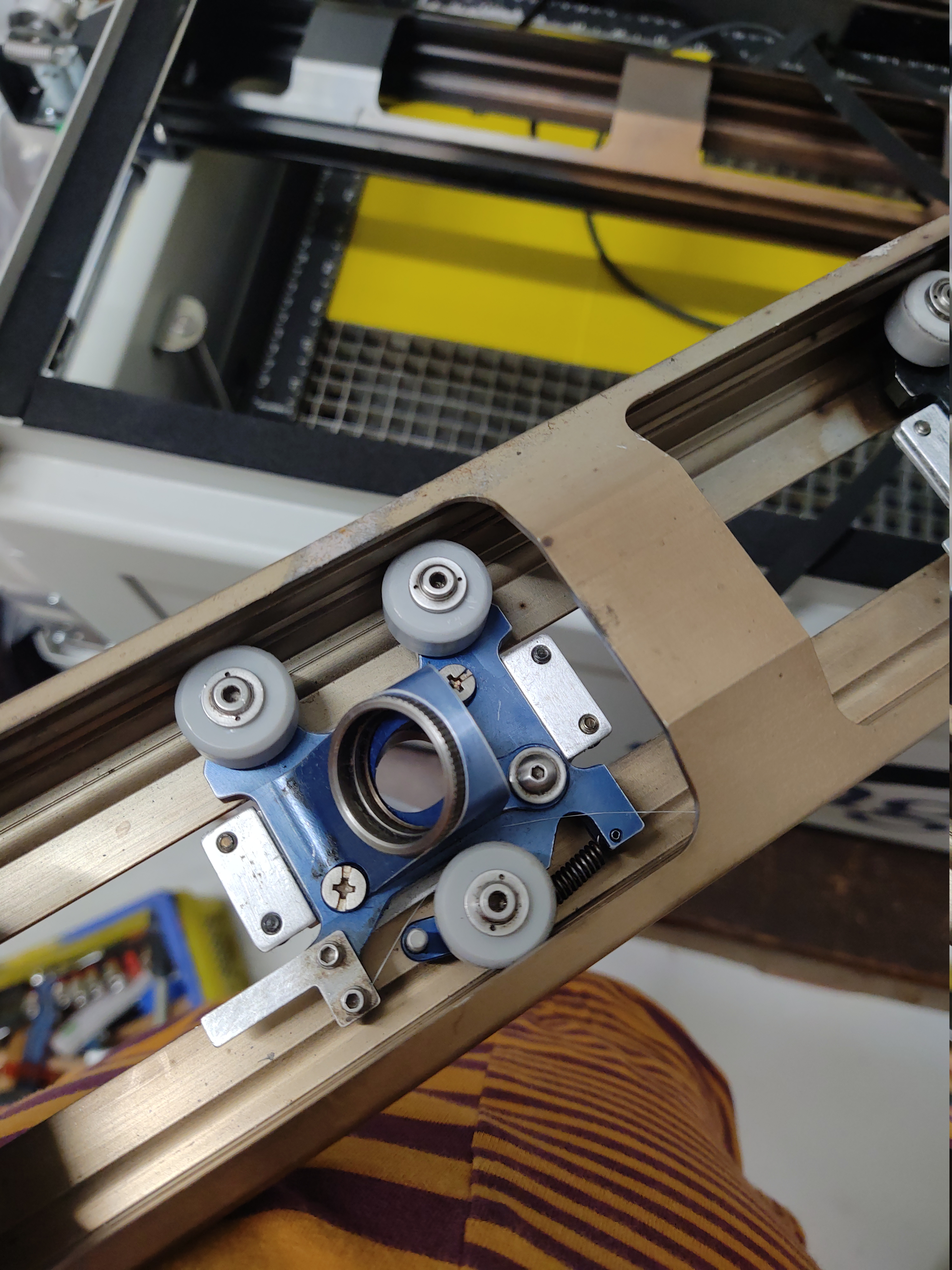

We also produced many spare parts ourselves using (reverse) engineering - for example, new foam seals for the vector grid, cover brackets using FDM 3D printing, plastic rollers for the carriage using DLP 3D printing, a suitable laser target for beam alignment, acrylic rear panels and a new ruler for the vector grid.

Photos

Why all the effort?

All in all, repairing the laser took about 70-100 hours. That's a lot. But it was worth it for us. The device is now well documented, we have gained a lot of know-how and it is no longer a black box for us. For example, we have learned how to adjust mirrors correctly in order to have a cleanly focused laser beam.

For us Makerspace'ers, repairing machines is an important activity as it keeps us fit, educates us and provides us with knowledge.

What happens next?

The laser is almost ready for use (except for the missing focus gauge). Unfortunately, we are still missing a few things to make the device suitable for everyday use. Among other things, we still need the right air compressor for the Air Assist, an extraction system with pre-filter, as well as a few practical aids such as interior lighting and a webcam for component placement. These are our project tasks for this year. We also need to determine the net power of the laser source using a measuring device and create a stable software workflow including suitable engraving and cutting parameters (material database). We use Inkscape and Visicut, among others, for this.

In addition, the laser should of course be available for use by members and be used for club projects and collaboration - for example for workshops. For this reason, machine instructions and the connection to FabAccess are planned.

Thanks

The effort was worth it. We would like to thank

- Maik for gaining and transporting the lasers to Chemnitz and giving us hope

- Ronny for making a longer prototype series for the resin rollers for the sled

- Mathieu for the second brain and for his support in dismantling, repairing and organizing

- Anselm for hauling the lasers and scrapping the rough old parts

- VOW Community for clarifying spare parts information

- Markus from Markusstr. for providing the space, infrastructure and trust in us for the repairs

- HQM Induserv for the professional cleaning of the vector grid

- cameo Laser Franz Hagemann GmbH for providing spare parts to us

Naming

As our new old laser has been reborn like a phoenix from the ashes, it is now called “Fawkes” - to match Dumbledore's bird from Harry Potter.

Open Source Hardware

The repair steps have brought some things to light. We will be filling the Git repo https://gitea.fablabchemnitz.de/FabLab_Chemnitz/epilog-zing-24 with information and downloads for spare parts in the near future.

Comments