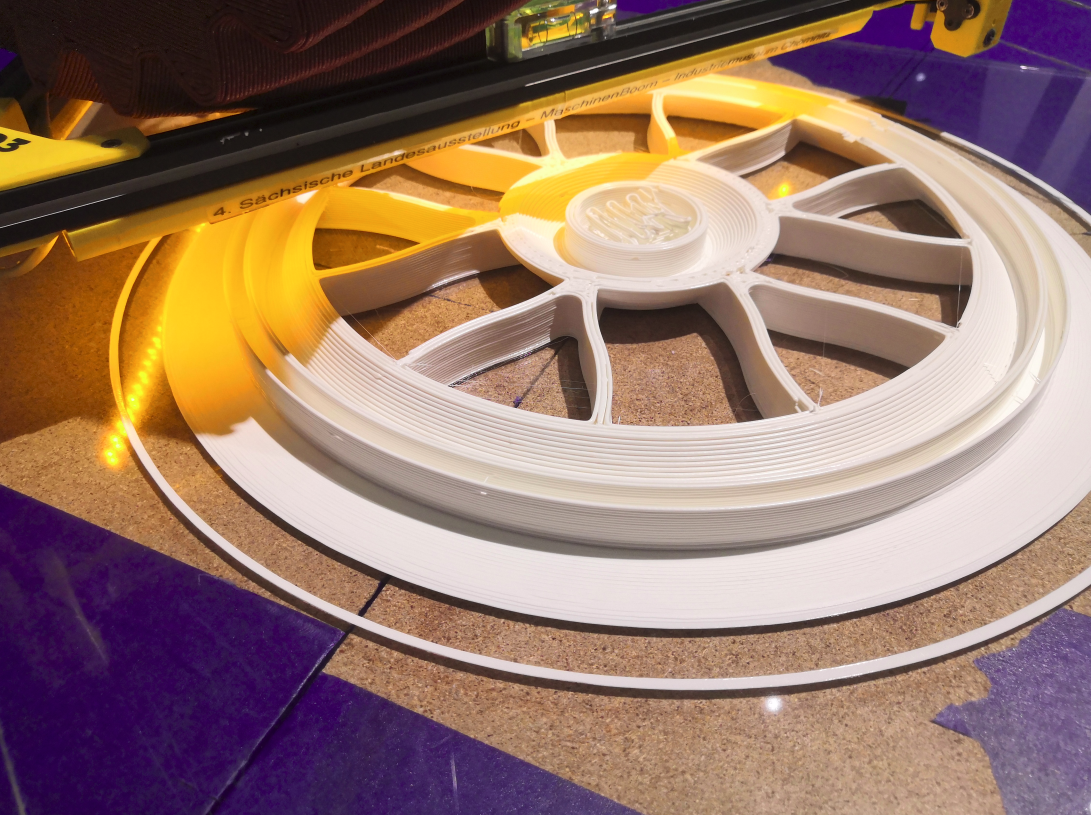

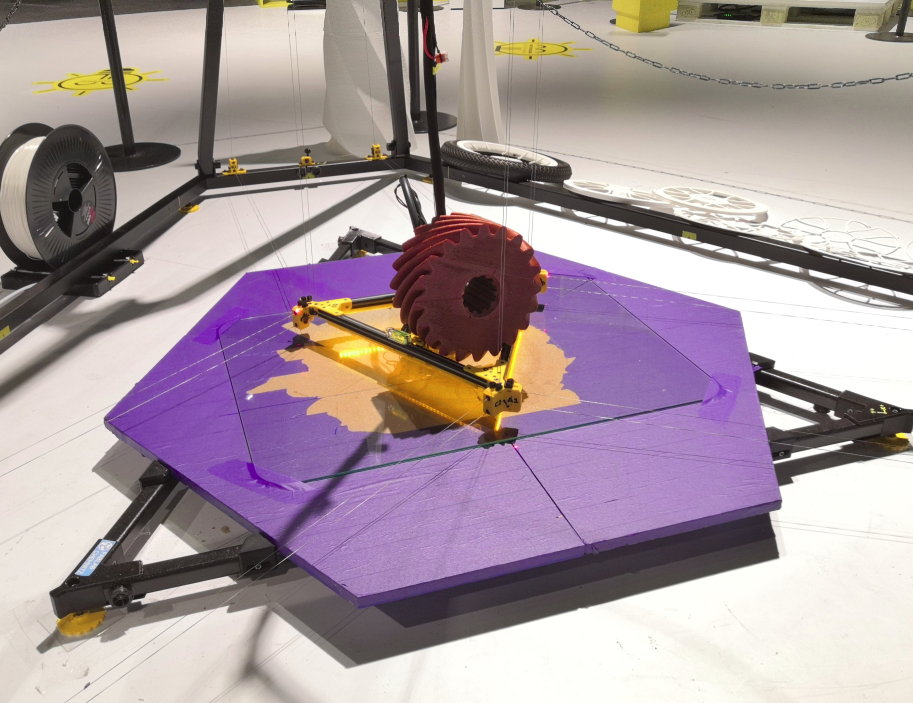

A week is over that quick. Yesterday was a good day! Thinking about the issues, reported in Reinventing the wheel :-P and A series of print failures (and some adjustments!), i came up with a smooth VSG safety glass plate with dimensions 600x800x4 mm (thankfully provided by the glaziers workshop of our local Holzkombinat). In addition to the new platform i also used that magic 3DLac spray again. As it seems this solution, in conjunction with a larger brim setting (+25mm) in PrusaSlicer, finally fixed the bottom region warping and we also receive a really clean surface now. Stay tuned to see the result next weekend. I had to pause the print due to lack of presenting time. Hopefully i am able to remove the printed part from the platform with ease. As the glass platform is not segmented it will be a little bit harder than usual.

Some more documentation

While testing i updated the docs of Trikaruis accordingly with some new stuff: Continuing prints over long set of days works fine. I added a new trigger script which automatically moves up the print head when pausing the print to avoid melting the actual print with a paused and active hotend.

I also made some small video which shows some consecutive symptoms like slack D lines and a humbling effector.https://videos.stadtfabrikanten.org/videos/embed/f23d831e-9183-4b4b-95e1-89ef51b2a137

Warping and slack lines as a result of partial peeling.

By The way i need to adjust the firmware anchor positions to include the glas plate's Z offset value:

#changed to add 4 mm offset

#old:

M669 A0.0:-1166.00:-21.13 B1010.00:585.00:-25.26 C-1015.00:578.00:-28.55 D2617.33 ;coordinates of anchor points

#new:

M669 A0.0:-1166.00:-17.13 B1010.00:585.00:-21.26 C-1015.00:578.00:-24.55 D2617.33 ;coordinates of anchor points

Comments